BAG FILLING MACHINES

Gross Bag Filling Machine

During the filling process, bag is continuously weighed in TKL type bag-filling machine. When the bag reached to the demanded weight, filling process ends. Feeding process has two speed steps: one fast; for reducing the filling time, and one slow; for achieving accuracy. Slow and fast feeding weight values can be entered from the operator panel.Optionally, a manual sewing machine can be added to TKL type bag filling machine. If all system considered being automatic, this sewing part can also be automatic.If the material to be filled is a hard flow material, a vibration unit or a pulse system can be added to ease the flow.

|

|

|

Net Bag Filling Machine

In TKC type packaging machine, weighing is realized on a bunker, which is in the discharge part of the feeding system. When the weigh bunker reaches to the requested weight, gates of TKC opens and the material falls into the bag. Feeding process has two speed steps: one fast; for reducing the filling time, and one slow; for achieving accuracy. Slow and fast feeding weight values can be entered from the operator panel. Not like gross weighing machine in net filling machines bag changing and weighing operations can be realized at the same time.

|

|

|

|||||||||||||||||||||||||||||||||

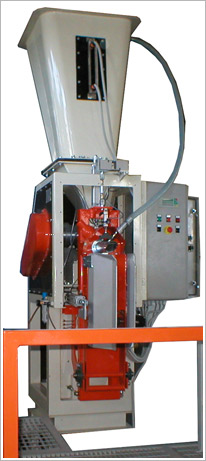

Valve Bag Filling Machine (Pneumatic Feeding)

SAFMAK’s design, valve bag filling machines is appropriate for filling of every kind of powder or granular materials into paper, plastic or polypropilen bags fast and accurately. SAFMAK designs and manufactures valve bag-filling machines differently according to the characteristics of the filling material.

There is a stock vessel inside the valve bag-filling machine, to stock the material. The material level inside the vessel is observed by vibration level sensors. This vessels bottom has a 30° slope, which one end is opened directly to the bag. By applying ~0.6 bar air from 5 different points of this vessel material is fluidized. Fluidized material flows through the nozzle unit and into the bag. The nozzle unit is connected to the stock vessel flexibly and it is weighed by two Load-Cells, which it is hanged on to. It is also designed to change easily considering the differences in bag sizes.

Flowing of material in the vessel has two speed steps: one fast; for reducing the filling time, and one slow; for achieving accuracy. A double step, pneumatic operated piston throttles the flex hose, between the nozzle and the vessel, in order to achieve slow feeding.

System is controlled by a PLC (Siemens) Unit and below items can be observed or changed from the Operator Panel:

- Weighing Values

- Fast-Slow Feeding Values

- Filling count

- Active weighing value

- Calibration Coefficient

- And Error Messages

|

|

Valve Bag Filling Machine (With Screw Feeder)

SAFMAK’s design, valve bag filling machines is appropriate for filling of every kind of powder or granular materials into paper, plastic or polypropilen bags fast and accurately. SAFMAK designs and manufactures valve bag-filling machines differently according to the characteristics of the filling material.

There is usually a feeding-equipment, which is connected with a flexible hose to the material silo. This feeding equipment can be belt feeder, or two different sized screw feeders. A weighing bunker is placed to the end of this feeding equipment, and this bunker is hanged with two Load-Cells. Under the weighing bunker there is a pneumatic operated lide. Weighing bunker is placed inside a cover whose bottom has a small screw feeder to transmit the material into the bag.

|

|